Bag Houses

Strict dust emission limits or dust peaks can push the electrostatic precipitator to its limits.If the existing casing is in good mechanical condition, the conversion from an electrostatic precipitator to a bag house may be the best solution. This ensures that space problem for new plant components can be avoided and the ongoing usability of the dust conveyor without any conversion.

This way, there is no need for an application review for a completely new plant, which is often a bigger hurdle than the conversion itself. ELEX builds ReverseAir and PulseJet filters for this purpose.

UMBAUTEN /

UPGRADES

Durch den Umbau von bestehenden Anlagen können mit relativ geringem Aufwand Kapazitätserhöhungen bewältigt oder neue Grenzwerte eingehalten werden. Umbauten erfordern ein hohes Mass an Erfahrung, da teilweise während des laufenden Betriebes und/oder in beengten Platzverhältnissen gearbeitet werden muss. Eine lange Liste von Referenzen ist der Beweis für die hohe Qualität unserer Umbaukonzepte. Dabei ist es uns wichtig, nur alles wirklich Notwendige zu ersetzen und bestehende Komponenten bestmöglich weiter zu verwenden.

Mögliche Varianten sind:

– Anbau von zusätzlichen Feldern

– Umrüstung von Fremdfiltern auf ELEX-Standard

– Erweiterung der Niederschlagsfläche durch Verlängerung der Feldlänge

– Einsatz alternativer HS-Technologien (SMPS oder Dreiphasen-Aggregate)

– Umrüstung von Elektrofiltern auf Hybridfilter

– Umrüstung von Elektrofiltern auf Gewebefilter

SCOPE OF APPLICATION

Our bag filters are the result of decades of experience and relentless research into the achievable optimum.

Bag filters are most frequently used in the cement industry and for coal- or biomass-fired boilers. A discussion with us will clarify what the optimal solution is in your case.

SUCCESS FIGURES

We have a wealth of experience in the manufacturing of bag filters with different numbers of hoses and differential pressures. We would like to convince you not just with words, but also prove our expertise and know-how with facts and figures.

54

Bag

houses

12-16

mbar DIFFERENTIAL PRESSURE

4434

FILTER BAGS

REFERENCES

Thanks to decades of experience and countless measurements carried out, ELEX has a huge wealth of experience. Below we have listed a small excerpt from our references. For further reference information or if you are interested in a plant visit, please contact us.

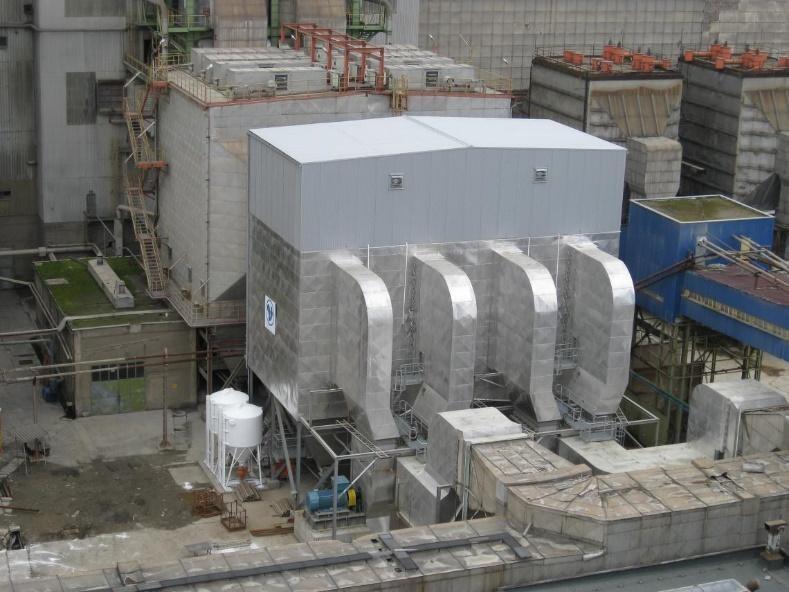

Installation: Kakanj (Bosnia-Hercegovina); Bag house for lignite-fired boiler

Installation: Perlen (Switzerland); Bag house to biomass fired boiler

Müll- und Schlammverbrennungsöfen

Thanks to decades of experience and countless measurements carried out, ELEX has a huge wealth of experience. Below we have listed a small excerpt from our references.

Für weitere Referenzauskünfte oder bei Interesse für einen Anlagenbesuch nehmen Sie bitte Kontakt mit uns auf.

Would you like more references?

Please enter your e-mail address:

SERVICES

ELEX gas cleaning systems are characterized by very high availability and low maintenance costs. However, if a malfunction occurs, rapid assistance is irreplaceable. In case of emergency, we are there for you and provide you with competent and reliable support on site.